Inqubo Yokucwenga Uwoyela Odliwayo: I-Water Degumming

Incazelo Yomkhiqizo

Inqubo ye-Degumming esitshalweni sokucwenga uwoyela ukususa ukungcola kwezinsini kuwoyela ongahluziwe ngezindlela ezingokomzimba noma zamakhemikhali, futhi yisigaba sokuqala senqubo yokucwenga / yokuhlanza uwoyela. Ngemuva kokucindezelwa ngezikulufu kanye nokukhipha isincibilikisi ezinhlotsheni zamafutha, uwoyela ongahluziwe ikakhulukazi uqukethe ama-triglycerides kanye nama-non-triglyceride ambalwa. Ukwakheka okungeyona i-triglyceride okuhlanganisa ama-phospholipids, amaprotheni, i-phlegmatic noshukela kungasabela nge-triglycerides yakhe i-colloid, eyaziwa ngokuthi ukungcola kwezinsini.

Ukungcola kwegum akuthinti nje ukuzinza kwamafutha kodwa futhi kuthinta umphumela wenqubo yokucwenga uwoyela nokucubungula okujulile. Isibonelo, uwoyela ongahluziwe kulula ukwenza uwoyela owenziwe nge-emulsified enqubweni yokucwenga i-alkaline, ngaleyo ndlela andise ubunzima bokusebenza, ukulahleka kokucwenga uwoyela, kanye nokusetshenziswa kwezinto ezisizayo; enqubweni ye-decolorization, uwoyela ongahluziwe uzokwandisa ukusetshenziswa kwe-adsorbent futhi unciphise ukusebenza kahle kokushintsha umbala. Ngakho-ke, ukukhishwa kwezinsini kuyadingeka njengesinyathelo sokuqala enqubweni yokuhluzwa uwoyela ngaphambi kokususwa kweacidity kawoyela, ukubola kombala, nokuqeda iphunga likawoyela.

Izindlela eziqondile zokususa i-degumming zifaka i-hydrated degumming(i-water degumming), i-acid refining degumming, indlela yokucwenga i-alkali, indlela ye-adsorption, i-electropolymerization kanye nendlela ye-thermal polymerization. Enqubweni yokucwenga uwoyela odliwayo, indlela esetshenziswa kakhulu i-hydrated degumming, engakhipha i-hydratable phospholipids namanye ama-non-hydrate phospholipids, kuyilapho ama-phospholipids asele angewona ama-hydrate adinga ukususwa nge-acid refining degumming.

1. Umgomo wokusebenza we-hydrated degumming (i-water degumming)

Uwoyela ongahluziwe ovela enqubweni yokukhipha i-solvent uqukethe izakhi ezincibilikayo emanzini, ngokuyinhloko ezihlanganisa ama-phospholipids, okudingeka asuswe kuwoyela ukuze kuvunyelwe imvula encane kanye nokuzinza ngesikhathi sokuthutha uwoyela kanye nokugcinwa kwesikhathi eside. Ukungcola kwezinsini njengama-phospholipids kunesici se-hydrophilic. Okokuqala, unganyakazisa futhi wengeze inani elithile lamanzi ashisayo noma isixazululo samanzi se-electrolyte njengosawoti ne-phosphoric acid kuwoyela ongahluziwe oshisayo. Ngemva kwesikhathi esithile sokusabela, ukungcola kwezinsini kwakuzofingqwa, kunciphe futhi kukhishwe emafutheni. Enqubweni ye-hydrated degumming, ukungcola ngokuyinhloko kuyi-phospholipid, kanye namaprotheni ambalwa, i-glyceryl diglyceride, ne-mucilage. Ngaphezu kwalokho, izinsini ezikhishiwe zingacutshungulwa zibe i-lecithin ukuze kube ukudla, ukudla kwezilwane noma ukusetshenziswa kwezobuchwepheshe.

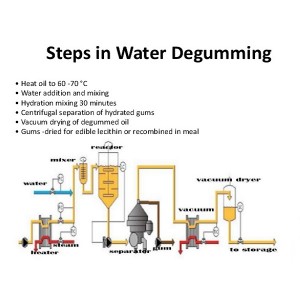

2. Inqubo ye-hydrated degumming (i-water degumming)

Inqubo ye-water degumming ibandakanya ukungeza amanzi kuwoyela ongahluziwe, ukufaka amanzi ezingxenyeni ezincibilikayo emanzini, bese kususwa iningi lazo ngokuhlukaniswa kwe-centrifugal. Isigaba esilula ngemva kokuhlukaniswa kwe-centrifugal uwoyela ongahluziwe we-degummed, futhi isigaba esinzima ngemva kokuhlukaniswa kwe-centrifugal inhlanganisela yamanzi, izingxenye ezincibilikayo emanzini kanye namafutha ahlanganisiwe, okubizwa ngokuthi "izinsini". Uwoyela ongahluziwe we-degummed uyomiswa futhi upholiswe ngaphambi kokuthunyelwa endaweni yokugcina. Izinsini ziphindiselwa ekudleni.

Embonini yokuhluza uwoyela, umshini wokukhipha uwoyela we-hydrated ungasebenza kanye nomshini wokuqeda uwoyela, umshini wokukhipha umbala, nomshini wokuqeda iphunga, futhi le mishini iwukwakhiwa komugqa wokukhiqiza ohlanza uwoyela. Ulayini wokuhlanza uhlukaniswa ngohlobo lwesikhashana, uhlobo oluqhubekayo, kanye nohlobo oluqhubekayo ngokugcwele. Ikhasimende lingakhetha uhlobo ngokwamandla alo okukhiqiza adingekayo: ifektri enamandla okukhiqiza ayi-1-10t ngosuku ilungele ukusebenzisa imishini yohlobo lwezikhawu, i-20-50t ngosuku ifektri ilungele ukusebenzisa imishini yohlobo eqhubekayo, ikhiqiza. ngaphezu kwe-50t ngosuku ilungele ukusebenzisa imishini yohlobo eqhubekayo ngokugcwele. Uhlobo oluvame ukusetshenziswa kakhulu ulayini wokukhiqiza we-hydrated degumming.

Ipharamitha yezobuchwepheshe

Izinto eziyinhloko ze-Hydrated degumming (i-water degumming)

3.1 Umthamo wamanzi angeziwe

(1) Umthelela wamanzi angeziwe ekunyakazeni: Inani elifanele lamanzi lingakha isakhiwo esizinzile se-multi-layer liposome. Amanzi anganele azoholela ekungeneni kwamanzi okungaphelele kanye ne-colloidal flocculation embi; Amanzi amaningi avame ukwenza i-emulsification yamanzi-amafutha, okunzima ukuhlukanisa ukungcola emafutheni.

(2) Ubudlelwano phakathi kokuqukethwe kwamanzi engeziwe (W) kanye nokuqukethwe kwe-glum (G) kuzinga lokushisa elihlukile lokusebenza:

| ukushisa okuphansi kwe-hydration (20 ~ 30 ℃) | W=(0.5~1)G |

| izinga lokushisa eliphakathi nendawo(60~65℃) | W=(2~3)G |

| izinga lokushisa eliphezulu le-hydration (85 ~ 95℃) | W=(3~3.5)G |

(3) Ukuhlolwa kwesampula: Inani elifanelekile lamanzi angeziwe linganqunywa ngokuhlolwa kwesampula.

3.2 Izinga lokushisa lokusebenza

Izinga lokushisa lokusebenza ngokuvamile lihambisana nezinga lokushisa elibalulekile (ukuze i-flocculation engcono, izinga lokushisa lokusebenza liphakeme kancane kunezinga lokushisa elibalulekile). Futhi izinga lokushisa lokusebenza lizothinta inani lamanzi angeziwe lapho izinga lokushisa liphezulu, inani lamanzi likhulu, ngaphandle kwalokho, lincane.

3.3 Ukuqina kokuxubana kwe-hydration kanye nesikhathi sokuphendula

(1) I-Inhomogeneous hydration: I-Gum flocculation iwukusabela okuhlukahlukene esibonakalayo sokusebenzisana. Ukuze wenze isimo se-emulsion samanzi esizinzile samafutha, ukuxuba ngomshini ingxube kungenza amaconsi ahlakazeke ngokugcwele, ukuxubana kwemishini kudinga ukuqiniswa ikakhulukazi uma inani lamanzi angeziwe likhulu futhi izinga lokushisa liphansi.

(2) Ukuqina kokuxubana kwe-hydration: Uma uhlanganisa amafutha namanzi, isivinini esishukumisayo singama-60 r/min. Esikhathini sokukhiqiza i-flocculation, isivinini esishukumisayo singama-30 r/min. Isikhathi sokuphendula sokuxuba kwe-hydration cishe imizuzu engama-30.

3.4 Ama-Electrolyte

(1) Izinhlobonhlobo zama-electrolyte: Usawoti, i-alum, i-sodium silicate, i-phosphoric acid, i-citric acid ne-dilute sodium hydroxide solution.

(2) Umsebenzi oyinhloko we-electrolyte:

a. Ama-Electrolyte angakwazi ukunciphisa amandla kagesi ezinhlayiya ze-colloidal futhi akhuthaze izinhlayiya ze-colloidal zibe sedimentate.

b. Ukuguqula ama-phospholipids angewona ama-hydrated abe yi-hydrated phospholipids.

c. I-Alum: usizo lwe-flocculant. I-alum ingakwazi ukumunca ama-pigments emafutheni.

d. Ukuze chelate nge ions metal futhi uwasuse.

e. Ukukhuthaza i-colloidal flocculation eduze nokunciphisa okuqukethwe kwamafutha e-flocs.

3.5 Ezinye izici

(1) Ukufana kwamafutha: Ngaphambi kokufakwa emanzini, uwoyela ongahluziwe kufanele ugqugquzelwe ngokugcwele ukuze i-colloid isatshalaliswe ngokulinganayo.

(2) izinga lokushisa lamanzi angeziwe: Uma kufakwa amanzi, izinga lokushisa lokwengeza amanzi kufanele lilingane noma libe ngaphezudlwana kwezinga lokushisa likawoyela.

(3) Ikhwalithi yamanzi engeziwe

(4) Ukuzinza kokusebenza

Ngokuvamile, imingcele yezobuchwepheshe yenqubo ye-degumming inqunywa ngokuya ngekhwalithi yamafutha, futhi imingcele yamafutha ahlukene enqubweni ye-degumming ihlukile. Uma unentshisekelo yokucwenga uwoyela, sicela usithinte ngemibuzo noma imibono yakho. Sizohlela onjiniyela bethu abangochwepheshe ukuthi benze ngendlela oyifisayo ulayini kawoyela ofanele ohlome ngemishini yokucwenga uwoyela ehambisana nawe.