30-40 ton/day Complete Parboiled Rice Milling Plant

Incazelo Yomkhiqizo

I-paddy parboiling njengoba igama lisho kuyinqubo yokushisa kwamanzi lapho ama-starch granules anezinhlamvu zelayisi agaywa nge-gelatin ngokufaka isitimu namanzi ashisayo.I-Parboiled rice millingisebenzisa irayisi elishisayo njengempahla eluhlaza, ngemva kwalokhoisihlukanisi se-paddyukuhlanza, ukucwiliswa emanzini, ukupheka, ukomisa nokupholisa ngemva kokwelashwa kokushisa, bese ucindezela indlela evamile yokucubungula irayisi ukuze ukhiqize umkhiqizo werayisi. Irayisi eliphehliwe eliqediwe likumunce ngokugcwele umsoco werayisi futhi linokunambitheka okuhle, futhi ngesikhathi sokubilisa labulala izinambuzane futhi lenza irayisi ukugcineka kalula.

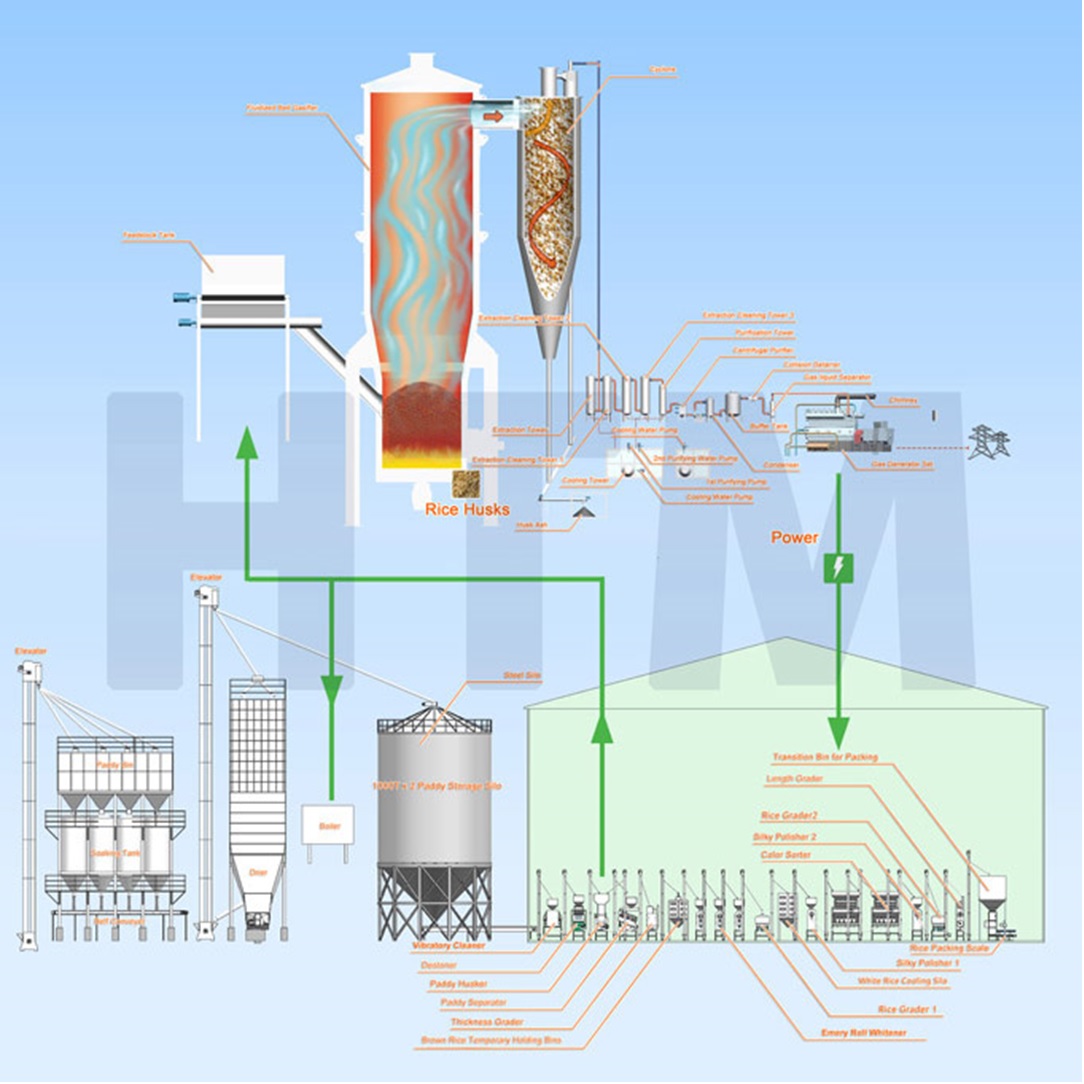

Siyakwazi ukuhlinzeka ngemishini yesimanjemanjeisitshalo esiphelele sokugaya irayisi se-parboiledngamandla okukhiqiza ochungechunge ngesidingo sakho. Isitshalo esiphelele sokugaya irayisi esibilisiwe ngokuvamile senziwa izingxenye ezimbili eziyinhloko: ingxenye yokubilisa irayisi kanye nengxenye yokugaya irayisi.

Izici

1) Ukuhlanza i-paddy:Kulesi sigaba sisusa ukungcola okuvela ku-paddy.

Irayisi kufanele ihlanzwe kuqala ukuze kukhishwe utshani, amatshe, intambo ye-hemp, enye imfucumfucu emikhulu nokungcola okunjengothuli oluxutshwe elayisi. Uma i-paddy inothuli lapho icwiliswa izongcolisa amanzi futhi ibe nomthelela ekondlekeni kwerayisi. Futhi, ngemva kwenqubo yokuhlanza, ukwehluleka kwemishini yokucubungula ezansi nomfula noma ukulimala kwezingxenye kungagwenywa ngokuphumelelayo, okuyinqubo eyinhloko yesethi ephelele yemishini yokubilisa irayisi.

2) Ukucwiliswa kwe-paddy:Inhloso yokucwiliswa emanzini ukwenza i-paddy imunce amanzi anele, idale izimo zokunamathisela isitashi. Ngesikhathi sokunamathisela isitashi i-paddy kumele imunce amanzi angaphezu kuka-30%, noma ngeke ikwazi ukushunqisa ngokugcwele i-paddy esinyathelweni esilandelayo futhi ngaleyo ndlela ibe nomthelela kwikhwalithi yerayisi.

a. Ngokucofa, izinga lokushisa elingaguquki, nokucwiliswa komfutho, amanzi amuncwa ngokuphelele irayisi ngesikhathi esifushane, ukuze amanzi elayisi afinyelele ngaphezu kuka-30%, okuyisimo esidingekayo ukuze isitashi serayisi sigcwaliswe ngokuphelele. ngesikhathi sokupheka. Emgqeni wokukhiqiza irayisi elibilisiwe, lesi sigaba sokucubungula siyisigaba esiyisisekelo nesibalulekile.

b. Ngokuya ngezinhlobonhlobo kanye nekhwalithi yerayisi, izinga lokushisa lokucwiliswa ngokuvamile lingama-55-70 degrees, futhi isikhathi sokucwiliswa amahora angu-3.5-4.5.

3) Ukushisa nokubilisa:Ngemuva kokucwilisa ingaphakathi le-endosperm selinamanzi anele, manje sekuyisikhathi sokushunqisa i-paddy ukuze ubone ukunamathisela isitashi. Ukushisa kungashintsha ukwakheka kwerayisi futhi kugcine umsoco, ukwandisa isilinganiso sokukhiqiza nokwenza irayisi igcinwe kalula.

Kule nqubo, kusetshenziswa umusi onengcindezi ephezulu kanye nokushisa okuphezulu. Izinga lokushisa, isikhathi, kanye nokufana kokushunqisa kufanele kulawulwe ngokuqinile ukuze isitashi erayisi sigcwaliswe ngokugcwele ngaphandle kokweqisa.

Lapho isitashi gelatinization kwanele, umbala kusetshenzwe eseqedile parboiled irayisi kuyinto esobala uju-anemibala.

Ngokulungisa amapharamitha wokupheka, irayisi elibilisiwe elinombala okhanyayo, umbala omnyama ophansi, nombala omnyama lingacutshungulwa ngokuya ngezidingo zekhasimende.

4) Ukomisa I-Paddy Eshisiwe:Inhloso yokomisa ukwenza umswakama unciphe ukusuka cishe ku-35% ukuya cishe ku-14%, ukunciphisa umswakama kungenza irayisi igcinwe kalula futhi ihanjiswe, futhi kwandise kakhulu isilinganiso sokukhiqiza, njengoba isilinganiso esiphezulu selayisi singatholakala lapho irayisi igayiwe.

Sisebenzisa ukushisa kwe-boiler phakathi nale nqubo, iguqulelwa emoyeni ngokusebenzisa isishintshi sokushisa, futhi irayisi yomiswa ngokungaqondile, futhi irayisi elomisiwe alinakho ukungcola futhi alikho iphunga elingavamile.

Inqubo yokomisa ihlukaniswe izigaba ezimbili. Isigaba sokuqala esomisa ngokushesha, okunciphisa umswakama we-paddy kusuka ngaphezu kuka-30% kuya cishe ku-20%, bese ukomisa kancane ukwenza i-paddy yehlise ngokugcwele futhi inciphise izinga lokuqhuma okhalweni. Thuthukisa isilinganiso samamitha wonke.

5) Ukupholisa I-Paddy Ehlanganisiwe:I-paddy eyomile ithunyelwa endaweni yokugcina eqondile ukuze igcinwe okwesikhashana ukuze yehliswe ngokugcwele futhi ipholiswe ngaphambi kokuba icutshungulwe. Indawo yokugcina impahla yesilinda emile ifakwe isiphephetha-moya sokungenisa umoya, esingakhipha ukushisa okusele. Futhi wenze umswakama werayisi ngokulinganayo.

6) Irayisi Husking kanye Nokwehlukana:Ukusebenzisa umshini wokugoqa irayisi ukususa ikhoba le-paddy elomisiwe. Ngemuva kokucwiliswa kanye nokushunqisa kuzoba lula kakhulu ukugoba i-paddy futhi wonge amandla.

Isihlukanisi se-paddy sisetshenziswa kakhulu ekuhlukaniseni irayisi elinsundu ku-paddy ngomehluko wamandla adonsela phansi athile kanye ne-coefficient yokungqubuzana ezingxenyeni ezintathu: i-paddy, irayisi elinsundu, kanye nengxube yakho kokubili.

7) Ukugaya Ilayisi:Iparele lerayisi eliphehliwe libiza isikhathi esiningi kune-paddy evamile. Isizathu siwukuthi ngemva kokucwilisa irayisi kulula ukuba smectic. Ukuze sigweme le nkinga, sisebenzisa isigayo serayisi esiphephukayo futhi sikhulise isivinini esijikelezayo se-rice miller, ukudluliselwa kwebran yerayisi kusebenzisa uhlobo lwe-pneumatic ukunciphisa ukungqubuzana.

Umshini wokugaya irayisi uthuthukiselwe ukugaya irayisi, okuwubuchwepheshe obuthuthukisiwe bemishini emhlophe yokugaya irayisi njengamanje ukwenza izinga lokushisa lerayisi lehle, okuqukethwe kwebran kunciphe, kanye nokwenyuka okuphukile kwehle.

8) Ukupholisha Ilayisi:Inqubo yokupholisha irayisi iwukupholisha indawo yerayisi ngokufafaza amanzi, okunikeza ukwakheka kongqimba olubushelelezi lwe-gelatinous olwandisa isikhathi sokulondoloza. Igumbi lokupholisha elinwetshiwe ukuze kukhiqizwe irayisi lekhwalithi ephezulu. Irayisi elihle liza ngomshini wokupholisha, lizokwenza irayisi lokugaya libe nombala omuhle kakhulu futhi licwebezele, ngaleyo ndlela kwandiswe ikhwalithi yerayisi.

9) Ukulinganisa Irayisi:Umshini wokulinganisa irayisi usetshenziselwa ukusefa irayisi eligayiwe kahle nangokunembile emakilasini amaningana: irayisi lekhanda, elikhulu eliphukile, eliphukile eliphakathi, eliphukile elincane, njll.

10) Ukuhlunga Umbala Welayisi:Irayisi esilithola esitebhisini esingaphezulu lisenerayisi elibi, irayisi eliphukile noma ezinye izinhlamvu noma itshe. Ngakho lapha sisebenzisa umshini wokuhlunga imibala ukuze sikhethe irayisi elibi nezinye izinhlamvu.

Umshini wokuhlunga umbala umshini obalulekile wokuqinisekisa ukuthi singathola irayisi lekhwalithi ephezulu. Ukusebenzisa umshini wokuhlukanisa umbala werayisi ukuze uhlukanise izinto ezimbi, ezinobisi, ezinotshani, i-paddy, nezangaphandle. Isignali ye-CCD ngenkathi kuvaliwe ihloliwe. Uma kutholakala ukuthi kukhona irayisi elingafanelekile noma ukungcola ezintweni zokwakha, i-ejector izoshaya impahla enesici ku-hopper.

11) Iqedile Ukupakisha Ilayisi:Irayisi yokuqeda manje isilungile sithandwa nonke! Masisebenzise umshini wethu wokukala nokupakisha ozishintshayo ukuze siwenze abe izikhwama ezingu-5kg 10kg noma ezingu-50kg.

Lo mshini wokupakisha okalwa ngokuzenzakalelayo unebhokisi lempahla, isikali sokupakisha, umshini wokuthunga, nebhande lokuthutha. Ingakwazi ukubambisana nomsebenzi nayo yonke imigqa yokukhiqiza yerayisi yemodeli. Iwuhlobo lukagesi, ungalubeka njengekhompyutha encane, bese luqala ukusebenza. Ukuze umthamo isikhwama ukupakisha ungakhetha 1-50kg isikhwama ngamunye ngokusho isicelo sakho. Kulo mshini uzothola isikhwama sohlobo lwerayisi futhi unganikeza irayisi lakho kuwo wonke amakhasimende akho!

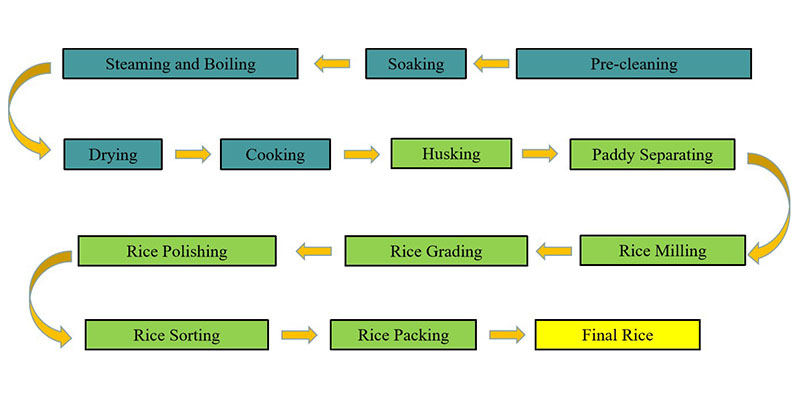

Kungabonakala enqubweni yokucubungula irayisi elibilisiwe ukuthi inqubo yokukhiqiza isethi egcwele yesitshalo se-paddy parboiling isekelwe kubuchwepheshe bokucubungula zelayisi elimhlophe, ukwengeza izinqubo zokwelashwa kwe-hydrothermal ezifana nokucwiliswa, ukubilisa nokubilisa, ukomisa nokupholisa, nokuphuza kancane. Yonke inqubo yokukhiqiza irayisi elibilisiwe ngokuvamile ihlanganisa izingxenye ezimbili: ingxenye ye-rice parboiling kanye nengxenye yokugaya irayisi, efana nalokhu:

Isigaba se-A.Rice Parboiling:

I-Raw Paddy → Ukuhlanza Ngaphambili → Ukucwiliswa → Ukushisisa Nokubilisa → Ukomisa → Ukupholisa → Ukugaywa Irayisi

Isigaba se-B.Rice Milling:

Iphedi Elishisiwe → Ukuhushula Nokwehlukanisa → Ukugaywa Ilayisi →Ukupholisha Ilayisi Nokugreda → Ukuhlunga Umbala Welayisi → Ukupakisha Ilayisi

Umgomo wokukhetha wokuphuma kwesitshalo se-paddy parboiling uncike kakhulu ekuphumeni namandla omshini wokugaya irayisi olandelayo. Kufanele kube nenani elanele lerayisi elibilisiwe ngaphambi kokuba inqubo yokugoqa irayisi iqale. Ukukhishwa kwemishini ekhishwe ngaphambilini kufanele kube kukhulu kunokukhishwa kwesigayo serayisi esilandelayo. Uma lokho kungenele, amayunithi amabili angaxhunywa ngokuhambisana. Uma okukhiphayo kuvumelana, sebenzisa i-pre-parboiler yerayisi enamandla amancane.

Siphayona embonini, sisebenza ekwakhiweni kwezinhlobonhlobo zePaddy Parboiling Plant. Singahlinzeka ngesitshalo esiphelele futhi sinikeze isevisi yokufaka kanye nesevisi yokuqeqesha. Uma unentshisekelo kule phrojekthi, sicela ukhululeke ukusithinta ukuze uthole ulwazi olwengeziwe.

Izici

1.Izitshalo zethu Zokubilisa & Zokomisa zenziwe ngezinto ezisezingeni eliphezulu nezihloliwe zekhwalithi yokuqala. Ukwakhiwa okuqinile okwenziwe kalula kuqinisekisa ukusebenza okungenazinkinga kanye nekhwalithi engcono efanayo.

2. Ukushiswa kwe-paddy ngendlela efanayo kwenzeka ngohlelo lokusabalalisa isitimu emathangeni, Ikhwalithi ephelele ye-paddy efanayo mayelana nokupheka nokomisa.

3.Amathangi amanzi amabili ahlinzekwa phezulu njengoba amanzi abandayo kulula ukuwaphakamisa.

4.Akukho ukuchithwa njengoba ukuphakama okwenyuka kwesitshalo kuqinisekisa ukugeleza okungcono kwe-taper ku-paddy emanzi.

5. Ukomisa irayisi ngendlela efanayo, ama-baffle aminyene ukuze ome kancane futhi kancane ngaphandle kokwakheka kokusanhlamvu okuphukile.

I-6.Factory ifakwe futhi ihlangene isitshalo ekwakhiweni kwe-bolting ngokugcwele nokugoqa, i-90% yezinto zokwakha ikhiqizwa embonini yethu, isikhathi esincishisiwe esithathwe ngesikhathi sokufakwa.

7.Ukusetshenziswa kwamandla okuphansi ngenxa yokuklama okuphumelelayo kwama-blower namakheshi.

8. Abasebenzi abaphansi abadingekayo ekusebenzeni kweyunithi njengoba imisebenzi eminingi izenzakalela.